Introduction

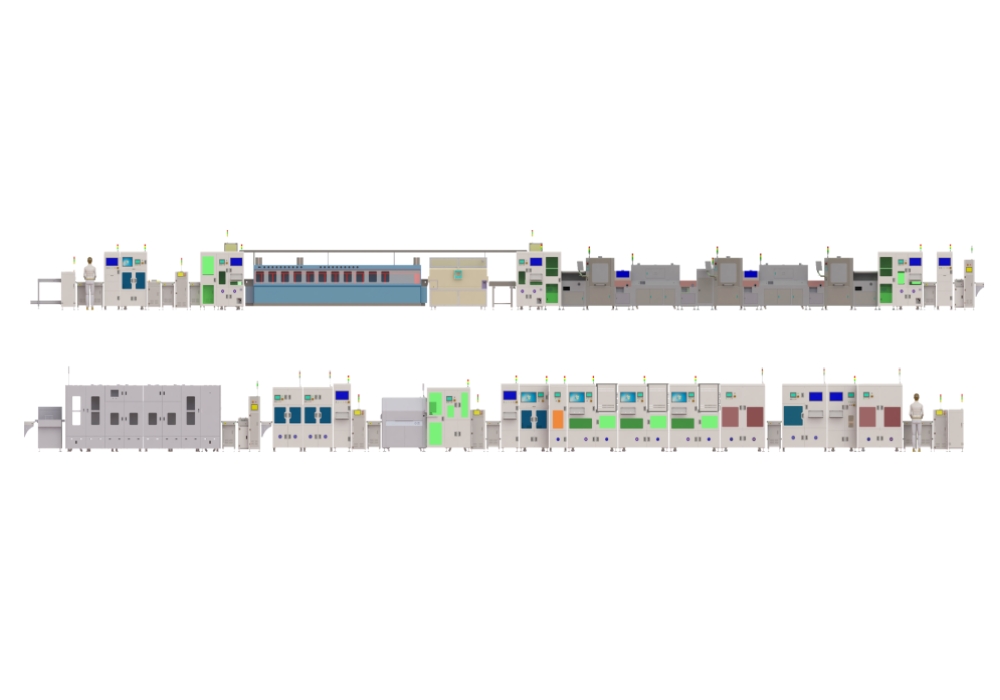

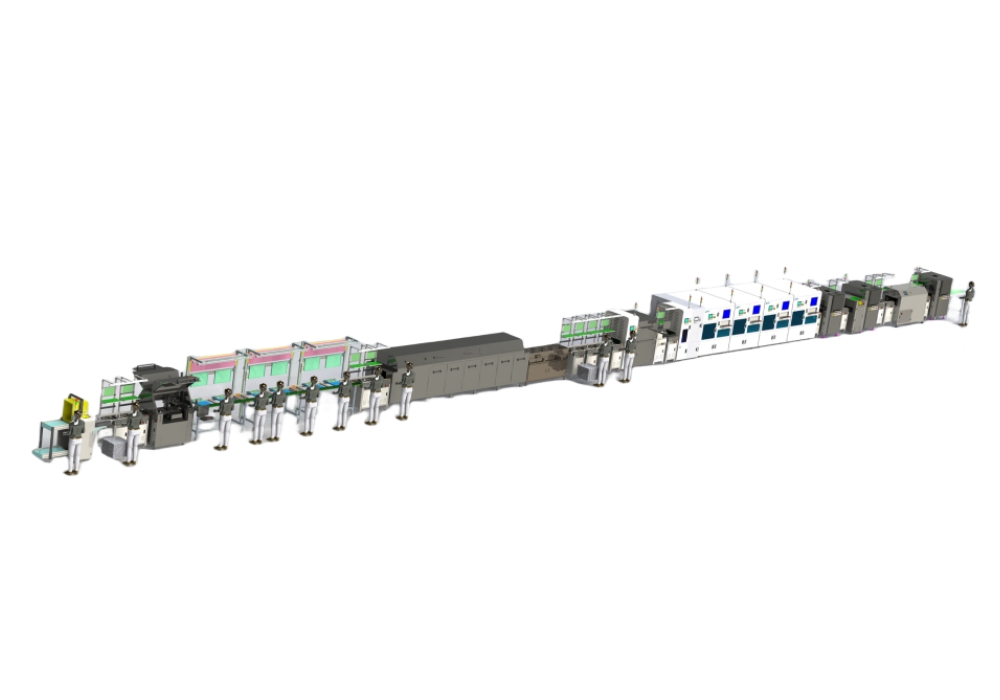

1.The driver automation production line is a solution tailored to customer needs. The production line realizes functions and applications such as brush heat dissipation, manual installation of support columns, assembly of upper and lower plates, insulation hose assembly machine, screw machine, burning, withstand voltage test, defective product cache repair, FCT, defective product cache repair, dispensing, aging, finished product testing, automatic shell assembly machine, assembly of waterproof rubber rings, air tightness detection, etc.;

2.Each PCB board needs to be laser-printed with a corresponding QR code;

3.The workstations in the production line that need to bind the workstation information to the product need to import a barcode scanner. When the product enters the workstation, the product is scanned and confirmed;

4.After the corresponding workstation completes the process of the product, the corresponding information is bound to the product;

5.Each workstation aggregates the information to the industrial computer end, and the system processes the information obtained and uploads it to the database for storage;

6.When tracing the product later, the information of each process station of the product can be retrieved by scanning the QR code on the product to facilitate confirmation of the problem.

Efficiency

UPH≥60

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 13538109318

Click the picture below to view more customer cases