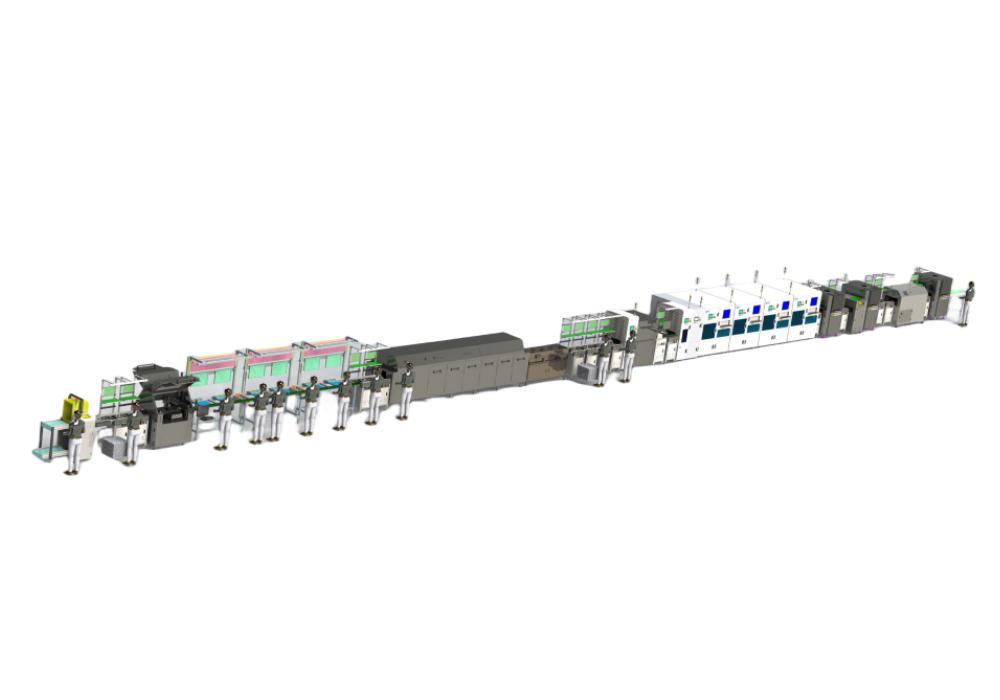

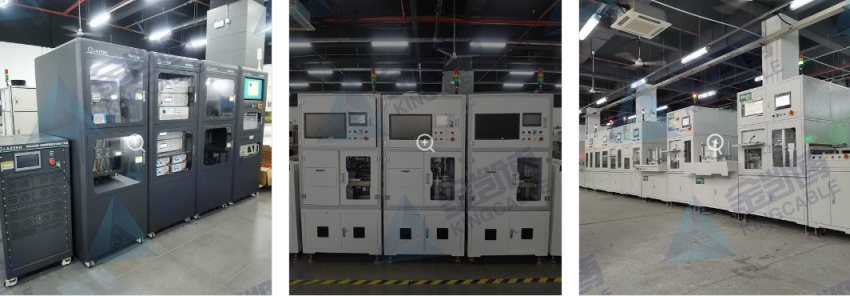

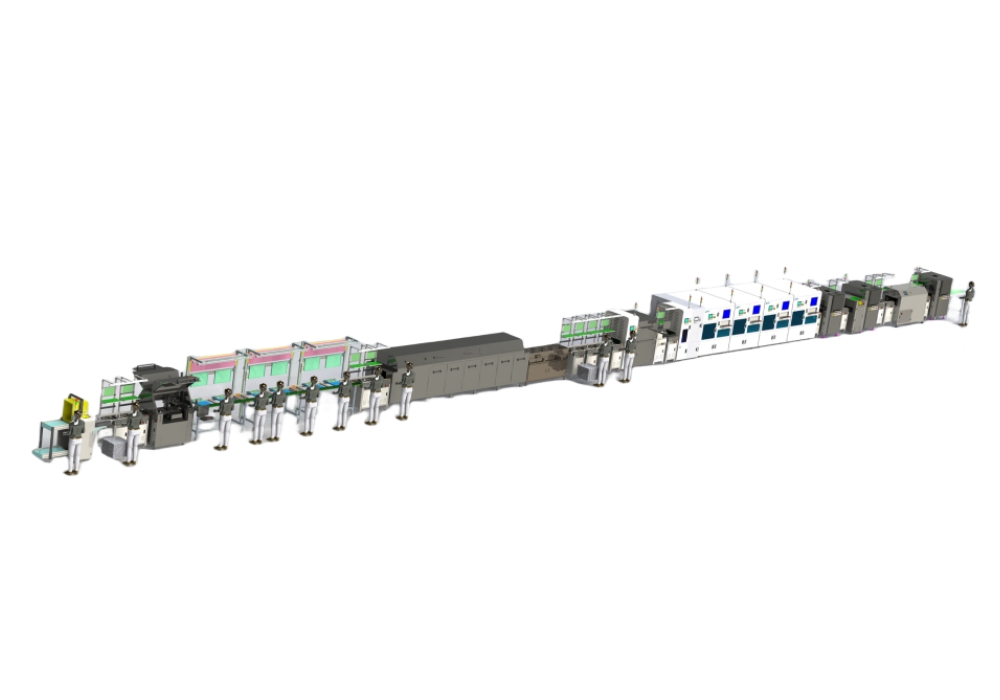

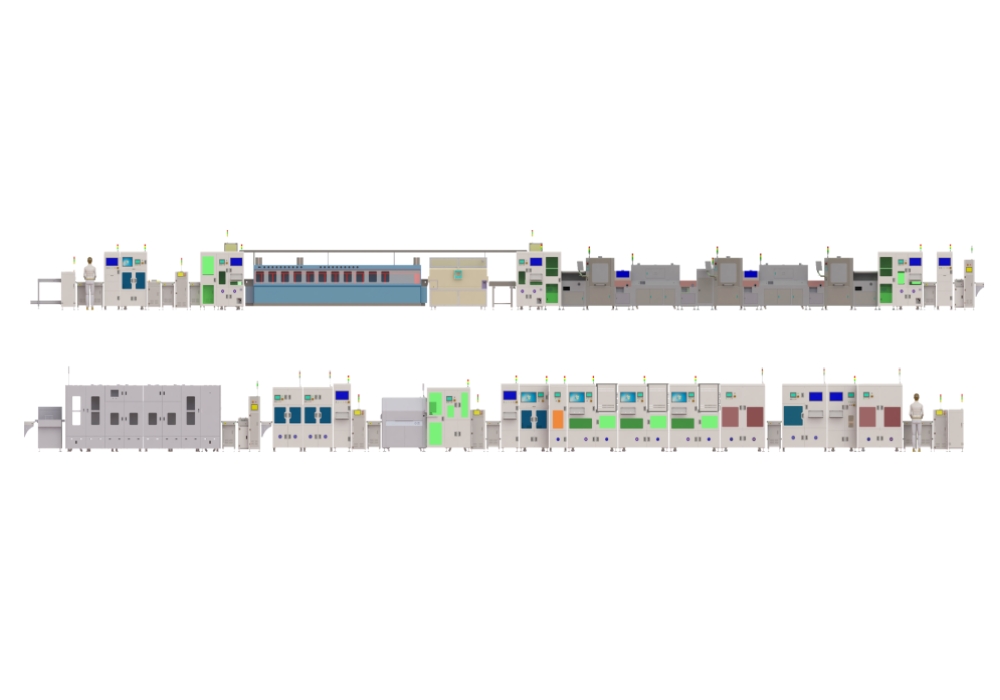

DIP Production Line Introduction

The PCB DIP automated intelligent production line ( DIP production line )realizes functions and applications such as automatic board loading, heat sink assembly, screw locking, plug-in, AOI, spray, wave soldering, cooling table, post-furnace AOI, code scanning, ICT, FCT, board separation, shell labeling, preheating, glue filling, curing, retesting, packaging, and boxing. Each unit realizes modular control. Large-screen displays can be installed at the pull head and pull tail to display the production and equipment status in real time, and reasonably plan the production line process and equipment layout to achieve the purpose of improving efficiency and saving costs.

Dip Production line E-SOP

1. Each workstation on the production line is equipped with a display screen to display the E-SOP of the corresponding workstation. Each workstation has its own E-SOP;

2. When the DIP production line is changed, the authorized personnel can switch the E-SOP of the corresponding model by selecting or scanning the product barcode on the application client;

3. When adding or deleting product models and maintaining E-SOP, the authorized personnel can operate and save on the application client;

4. The display installation is arranged and installed according to the actual situation on site to facilitate viewing and operation.

Application Industry

Applicable to the production, testing and assembly of intelligent white household appliances control panels, display panels, and control panels such as washing machines, air conditioners, refrigerators, and induction cookers. Whether in terms of cost investment, production efficiency or quality control, its performance and value far exceed traditional manual operations.

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 13538109318

Click the picture below to view more customer cases