Equipment Introduction

The remote control test equipment includes a body, a button click part for simulating pressing the infrared/Bluetooth remote control, a test fixture for locating the infrared remote control, and a receiving part for receiving infrared signals from the remote control paired with it. The equipment can help testers improve the efficiency of solving test problems during the development and manufacturing of electronic products, and can replace manual automatic testing to a certain extent, saving labor costs.

Test Function

1. Key function test: The function of each key can be tested through infrared decoding;

2. Static current test: The test accuracy can reach 0.01uA;

3. Dynamic current test: The dynamic current at the moment of infrared code transmission can be accurately tested, and the test accuracy is 0.01mA;

4. Backlight current detection: Detect the current value when the backlight is on, and the test accuracy is 0.01mA;

5. Irradiance test: Receive infrared signals through phototransistors, and convert signal strength into voltage values to judge irradiance;

6. Learning function: In learning mode, the device automatically learns infrared signals;

7. Carrier accuracy test: The carrier frequency, duty cycle, etc. can be accurately tested, and the test accuracy is better than 2%;

8. Visual inspection: High-precision camera detects LCD display, surface printing effect, backlight display, etc.;

9. Fake battery power supply: Voltage range o-5V, accuracy 0.01mV;

10. Equipment interface: Support MES system docking, download recipe files, and upload test data.

Process Flow

1. Manually place the four remote controllers to be tested in the left test loading position, press the left position button, and the workpiece enters the left test position for testing;

2. While testing the left position, manually place the four remote controllers to be tested in the right test loading position. After placing them, press the right position button, and the workpiece enters the right test position for testing;

3. After the left position test, according to the test results, the LED lamp beads at the OK product position will display green, otherwise the NG position lamp beads will display red. Manually place the product in the corresponding position according to the color displayed by the lamp beads;

4. Similarly, after the left position test, place the tested product in the corresponding position;

5. The industrial camera simultaneously detects the LCD display status of the four products being tested;

6. According to the production capacity requirements, the two workstations can be tested in turn in a ping-pong style, or they can be tested independently in parallel without interfering with each other.

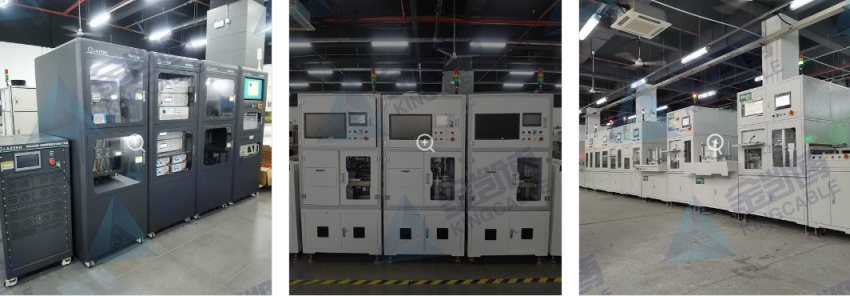

Double-station Parallel Testing Tooling

8 remote controllers can be tested simultaneously, and the industrial camera can monitor the LCD display of 8 remote controllers at the same time.

The two stations are independent of each other and can be tested in parallel, which effectively improves production efficiency.

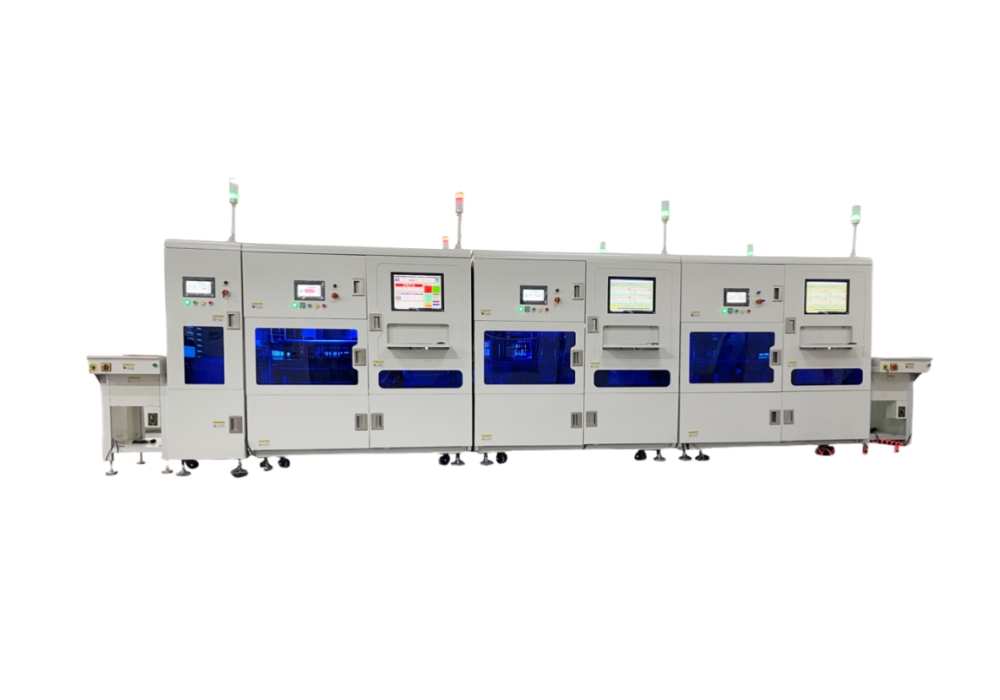

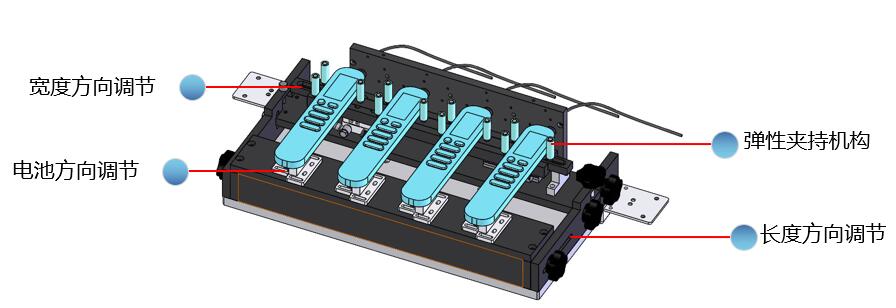

Universal Clamp

Can be quickly replaced and compatible with remote controls of different sizes and models

Parameter

| Equipment Beat | The total efficiency of the left and right dual systems is ≥650PCS/hour (0.6s for each button) with adjustable beats |

| Size Range | Compatible with remote controllers within 100mm wide × 350mm long |

| Test Formula | More than 100 machine model recipes can be saved, and the data can be modified; |

| Parameter Setting | The parameters of each button and each function can be configured separately, such as detection content, button time, current range, light intensity, silk screen, etc. |

| Misjudgment Rate | The overall misjudgment rate of the equipment is <0.1% |

| Failure Rate | The equipment failure rate is <0.5% (failure time/operating time) |

| Production Changeover Time | Quick-change fixture conversion time <5 minutes, universal fixture conversion time <15 minutes |

| Equipment Interface | Support MES system docking, download recipe files, upload test data |

| Specification | L1200mm*W 1000mm*H1700mm |

| Weight | 300KG |

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 13538109318

Click the picture below to view more customer cases