Functions

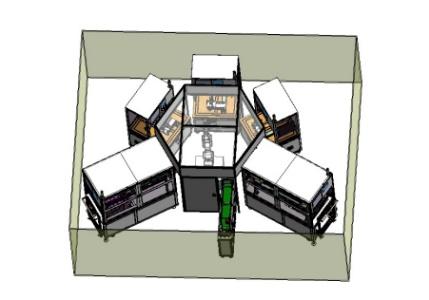

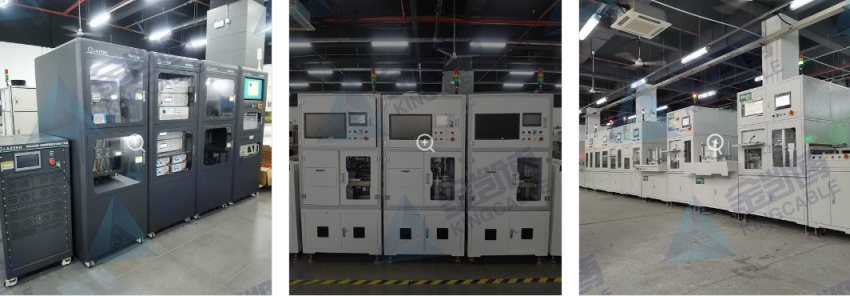

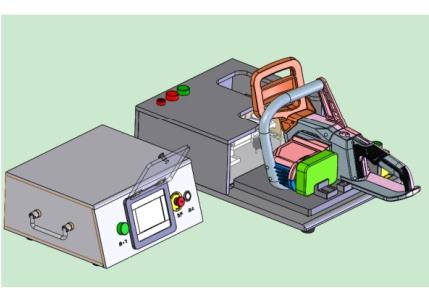

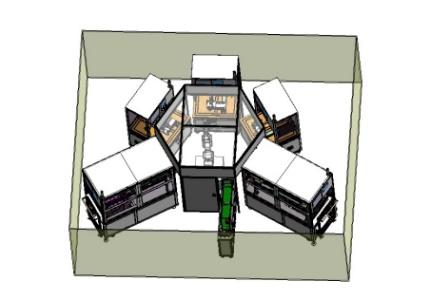

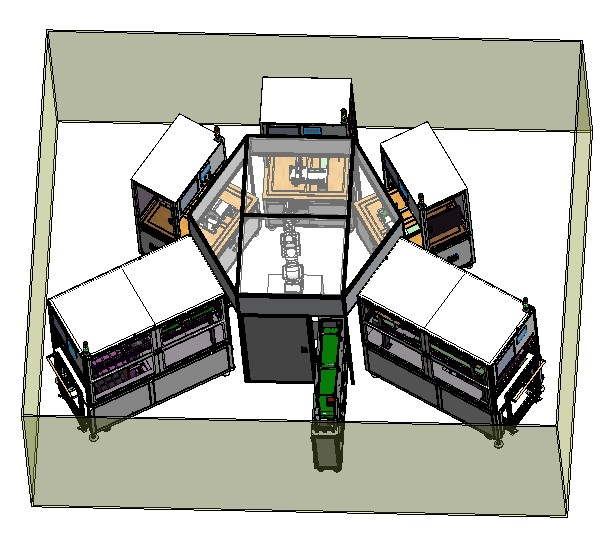

1. The material frame rises from the bottom of the feeder to the top, the robot recognizes and grabs it, and puts it into the corresponding test platform for testing;

2. The robot puts the defective products into the cache position for caching, and can cache 5-8 pieces;

3. When each material frame of the receiving machine is full, it descends. When all the material frames of the receiving machine are filled with material frames, the equipment alarm prompts manual removal.

4. Each device is an independent test device, which tests the corresponding PCB board separately. The layout is simple, easy to maintain, and subsequent compatibility with other products is also convenient and simple;

Efficiency

Capacity: 600 PCS/D

The test line is compatible with different functional PCBs of similar products (including mainboards, charging pile boards, communication boards and various small boards)

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 13538109318

Click the picture below to view more customer cases